Maktel Inc. has an experience over 50 years in the sector. Maktel Inc; Distance information about the working area of springs, cycle life expectancy, corrosion resistance requirements, ambient high/low temperature operation etc. to various sectors such as Defense industry, Aerospace, White Goods, Medical, Automotive, Energy, Electronics. offers R & D support with its team of highly experienced employees. Our facility is located in Maltepe, Istanbul, on open area of 21,000 m2; and closed area of 6200 m2; It has approximately 132 machines, 75% of which are CNC. It also includes state-of-the-art raw Materials Testing Devices, Spring Force Devices, Measurement Devices and Ascott Corrosion Test Device.

It can be manufactured in different sizes from EN 10270-1 DH/DIN 17223 D CLASS/EN 10270-2 CR-SI materials . Used in gun guns and non-grooved shotgun.

Manufactured in different sizes from EN 10270-1 DH/DIN 17223 D CLASS/EN 10270-2 Cr-Si materials. Used in grooved and grooveless hunting rifles. Used in light and heavy machine guns. Special alloy steel multi-wires (rope wire) are made from multiple wires on special machines. These springs are high performance springs.

Manufactured in different sizes from EN 10270-1 DH/DIN 17223 D CLASS/EN 10270-2 Cr-Si materials. Used in grooved and grooveless hunting rifles. Used in light and heavy machine guns. Special alloy steel multi-wires (rope wire) are made from multiple wires on special machines. These springs are high performance springs.

Manufactured in CNC machines from the raw material EN10270-1 DH / DIN17223 D Class. The Springs can be produced in any size.

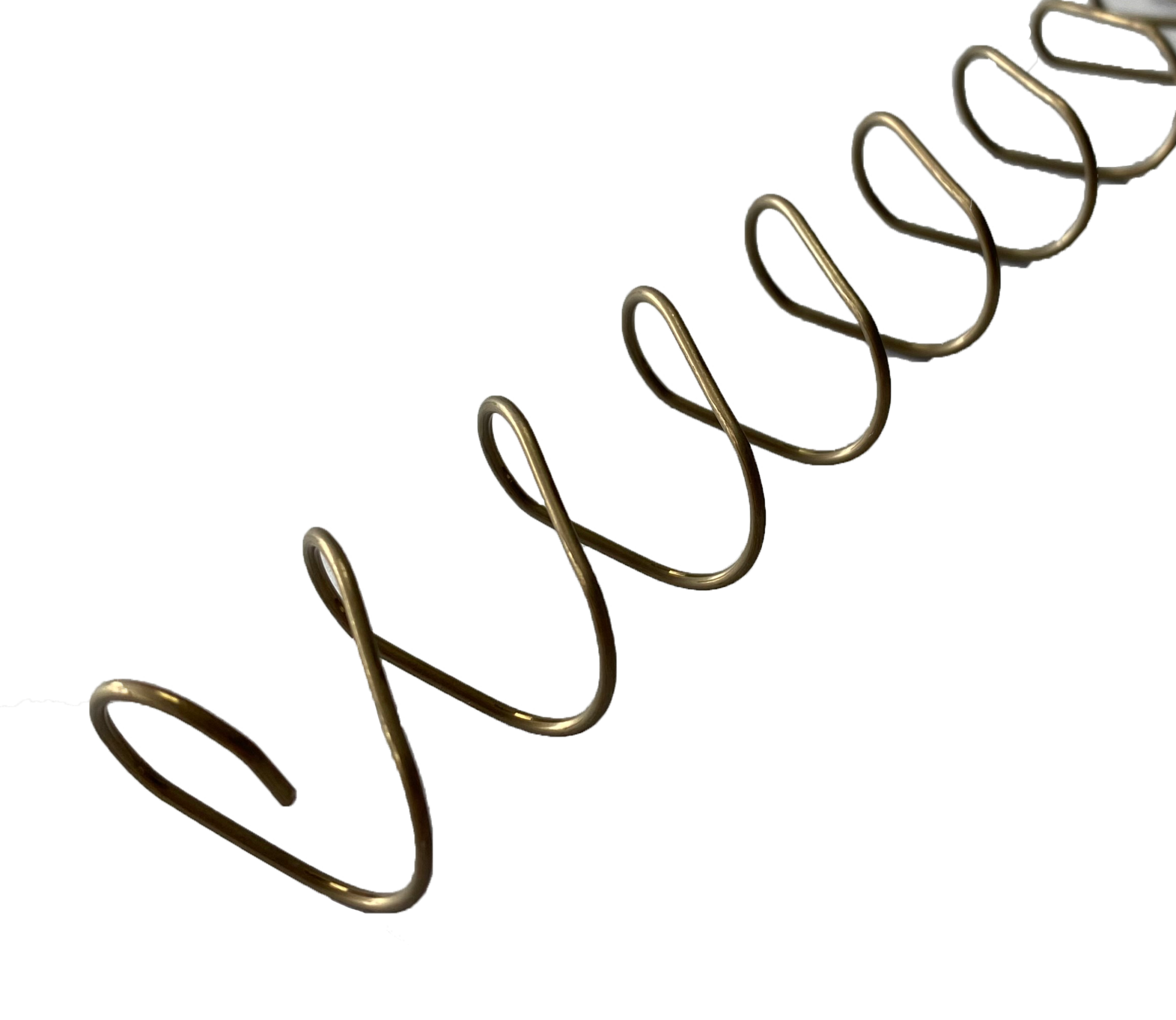

Produced form round or flat wire in special machines. Different model are available according to customer demands. Used in non ribbed hunting rifles.

When it comes to pressure springs, patented cold-ground wires, high-strength stainless wire, multi-wire and tempered valve in the highest-strength oil can be produced from all materials up to valve spring wire quality. In our company, we have the ability to work with any material from wire thicknesses within the diameter range of 0,20 to 8.00 mm. We can offer our customers a wide range of surface operations such as CR+ 3 zinc plated, Black oxide, Nickel coating and cataphoretic Paint. Grinding on springs, Cloning (Shot Peening) is done in our own constitution.

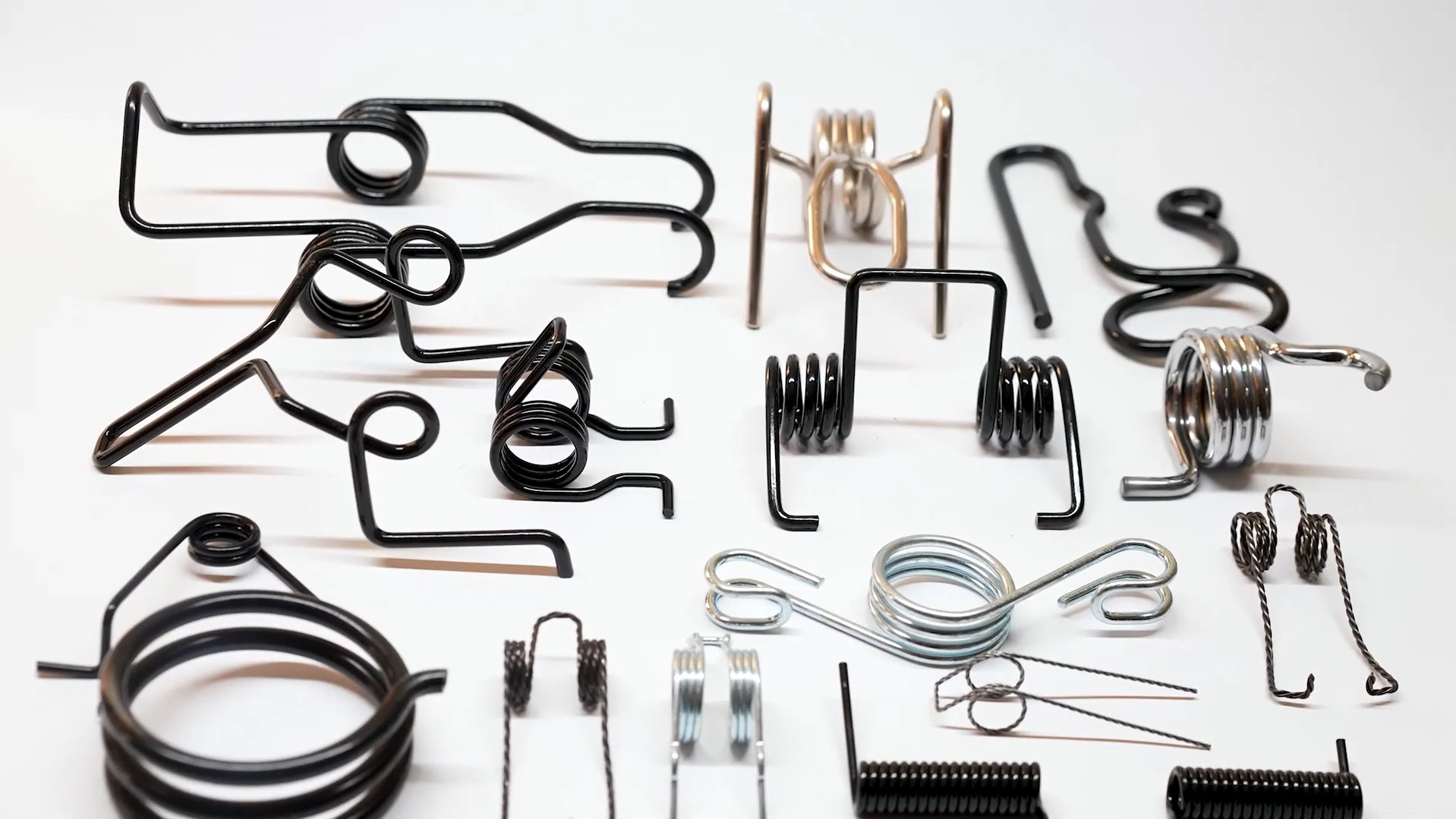

Torsion springs, used in many industries today, can be produced from a variety of spring steel, multi-wire and square-section materials. The force tests of the torsion springs are carried out in our own constitution. We also serve design in line with our customers' specific demands.

Nowadays, flat wires are among the essential design elements in many industries. They are mainly used in mechanical engineering, the defense industry, automotive, precision engineering, and electrical engineering. By absorbing or transmitting forces under relatively large deformations, they are potentially able to store energy and are able to be released again at any point over time. The flat springs are usually shaped straight, flat, curved, and helical. The application areas are unlimited and unpredictable. The tape springs also offer final surface operations such as blackout, zinc coating, cataphoretic paint, black oxide coating, and solid film lubricant.